At your service

Whether you need to fix a problem with an existing pump or find a pump for a new application, our team of engineers and technicians is here to help. With experience in nearly every industry, we can help you find the best solutions for your needs. We pride ourselves in designing and manufacturing our products in the USA. With fully integrated design, manufacturing, and testing, we aim to deliver robust and cost-effective solutions that exceed your expectations. Call us during business hours and you’ll always talk to a live person.

Over 85 Years of pump design and Application

Over our history, we’ve refined our pump design expertise by delivering tens of thousands of pumps into a wide variety of applications. We offer a variety of pre-engineered seal and lubrication systems to meet application-specific requirements. The rugged design of our pumps has been proven time and again in in military and API applications.

Exacting engineering and exhaustive testing ensure that our pumps provide:

- Heavy duty design and balanced rotodynamic forces for maximum reliability.

- Precise running clearances for efficiency and longer life.

- Ease of service and efficient hydraulics, for low lifecycle costs.

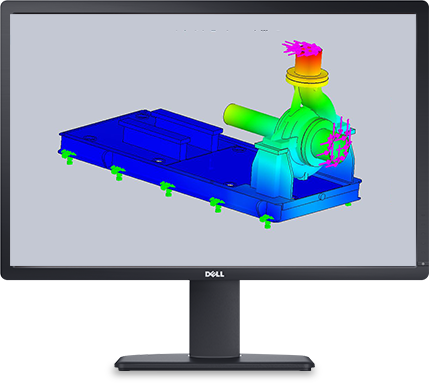

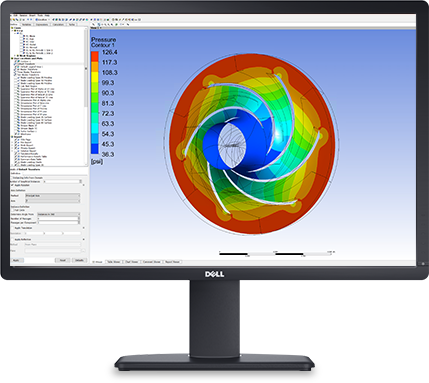

Applying the latest technology

Every new pump design undergoes a series of rigorous tests using computer simulation as well as in-laboratory testing. The latest finite element analysis (FEA) and computational fluid dynamic (CFD) software and advances in processing speed allow our engineers to optimize pump designs and troubleshoot before a prototype is built.

These tools allow us to:

- Achieve high-efficiency designs for low energy consumption.

- Predict and avoid noise, vibration and recirculation.

- Develop impellers for low NPSHa applications.

- Design inducers to meet challenging suction conditions.

- Rapidly design new components to rerate existing pumps.

Applying materials science for High-performance service

High-performance pumps require high-performance materials. We work regularly with a wide variety of materials including composites, stainless steels, nickel-based alloys and titanium. In addition, certain products can be rubber, neoprene or ceramic coated to meet difficult conditions at lower cost. Our in-house composites manufacturing capability lets us minimize lead time while controlling cost and quality. Our certified welders can fabricate and repair to military-grade standards. Destructive and non-destructive testing ensures that we deliver on our commitment to producing world-class engineered equipment.