850

Rugged in design and dependable in nature, the 850 is a proven performer in some of the earth’s toughest environments. Capable of operating in vacuum conditions up to 26″ Hg, the 850 is well suited for vacuum filtration and dewatering systems with difficult suction conditions. A vent port allows pumping to resume even after short periods of interrupted flow, assuring continuous pumping, from a trickle to full capacity.

With a semi-open impeller and a variety of material choices ranging from duplex stainless steel to rubber lined, the 850 is ideal for abrasives and light slurry duty in the mining, power generation, and pulp and paper industries.

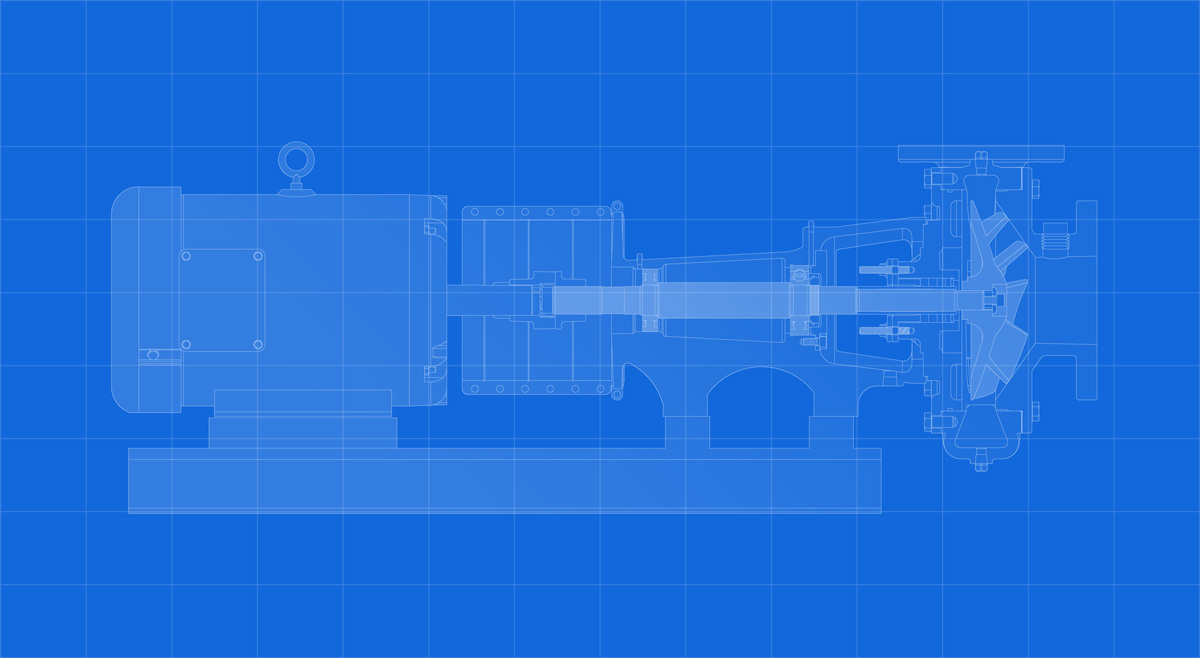

The 850 is available as either a close-coupled or frame-mounted unit with an option for a side-mounted motor with belt drive. By using either a belt drive or a variable frequency drive (VFD), performance can be fine-tuned to match most system requirements. The front and back pull-out design allows for easy maintenance. The pump comes standard with a packed stuffing box and flush water connections to ensure lubrication and eliminate vacuum or air leakage. A variety of shaft sealing options is available to meet the requirements of specific applications.

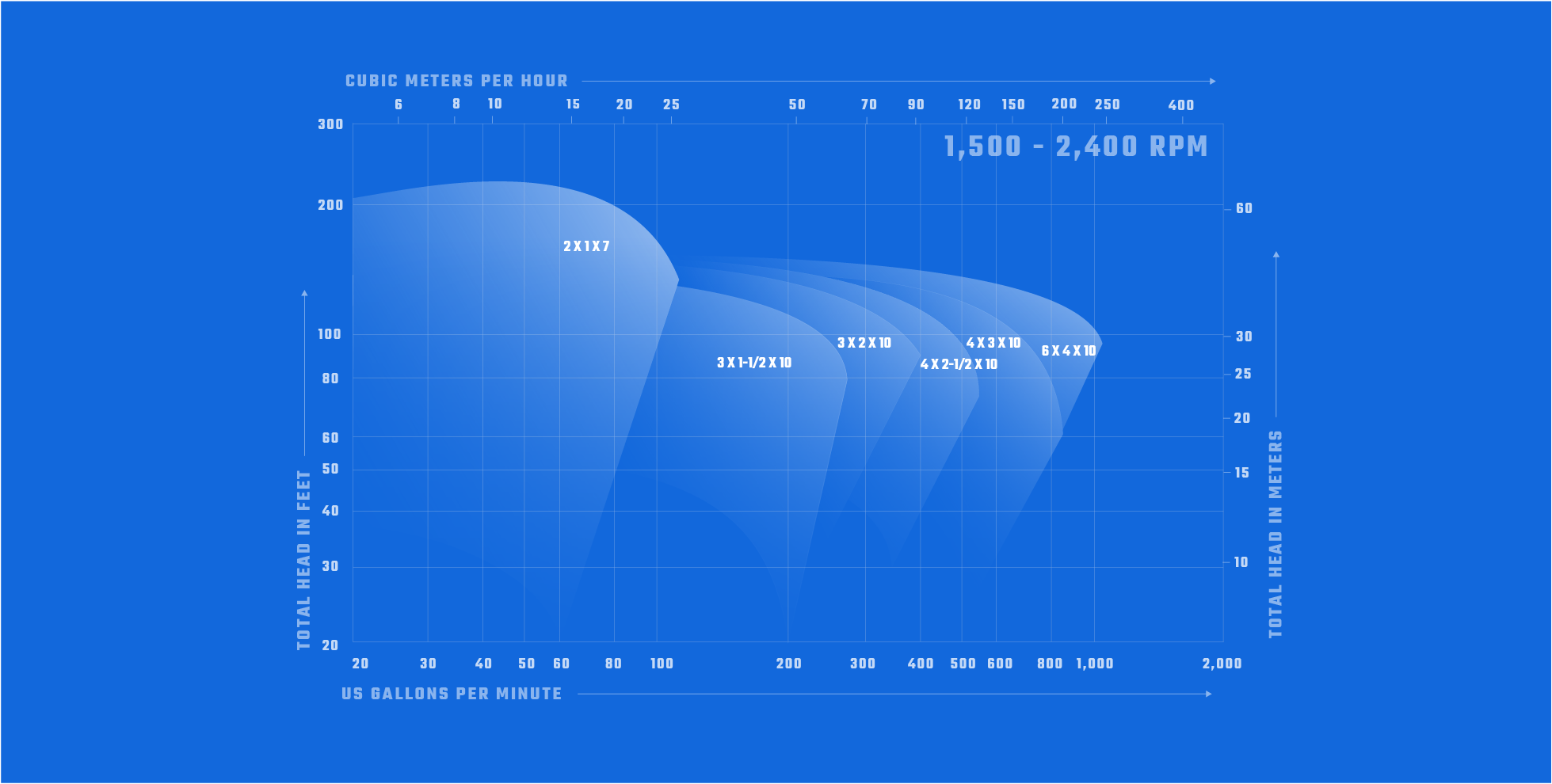

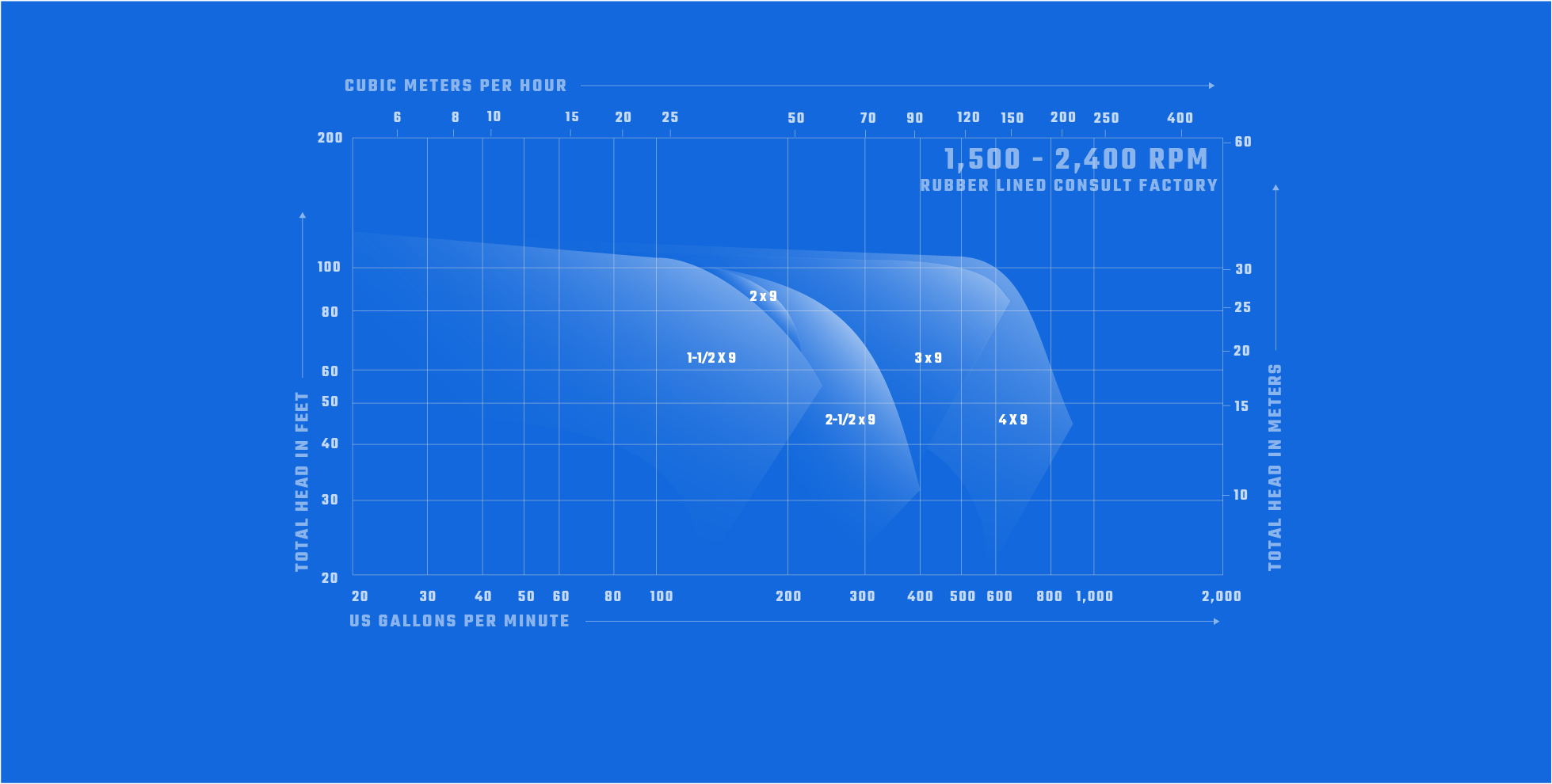

Hydraulics

Flows To

700 US GPM

159 m3/hr

Heads To

120 ft.

36 m

Power To

50 HP

37KW

Temperatures To

250° F

121° C

Speeds To

2,450 RPM

Hydraulic Coverage

Specifications

Materials of Construction

| Casing | Cast Iron, CD4MCuN or Rubber-Lined |

| Impeller | Cast Iron, CD4MCuN or Rubber-Lined |

| Shaft | Carbon Steel |

| Bearing Frame | Cast Iron |

| Other Materials Available Upon Request |

Design Data

| Rotation | Clockwise from Coupling |

| Input Power | Up To 50HP |

| Discharge Connection | Determined by Size |

| Bearings | Greased |

Features

Suction Flange

ANSI flat face cast iron or stainless steel flanges for all sizes.

Suction Vent Port

Allows pumping to resume even after short periods of interrupted flow.

Discharge

Depending on size, the pumps come with NPT or Class 150 ANSI flanged discharge connections. All rubber-lined pumps have flanged discharge.

Stuffing Box

Packed stuffing box as standard, mechanical seals are available as an option.

Back and Front Pull-Out Design

Allows removal of rotating elements and replacement of the shaft, impeller or mechanical seal without disturbing system piping.

Bearing Frame

Heavy-duty, thick-walled frame supports the rotor, assuring less vibration, better alignment and longer life.

Positively Locked Bearings

Grease-lubricated ball bearings secured by locknuts eliminate axial movement at the impeller-to-casing clearances.

Shafts

Large diameter shafts with replaceable 316 SS shaft sleeves.