855

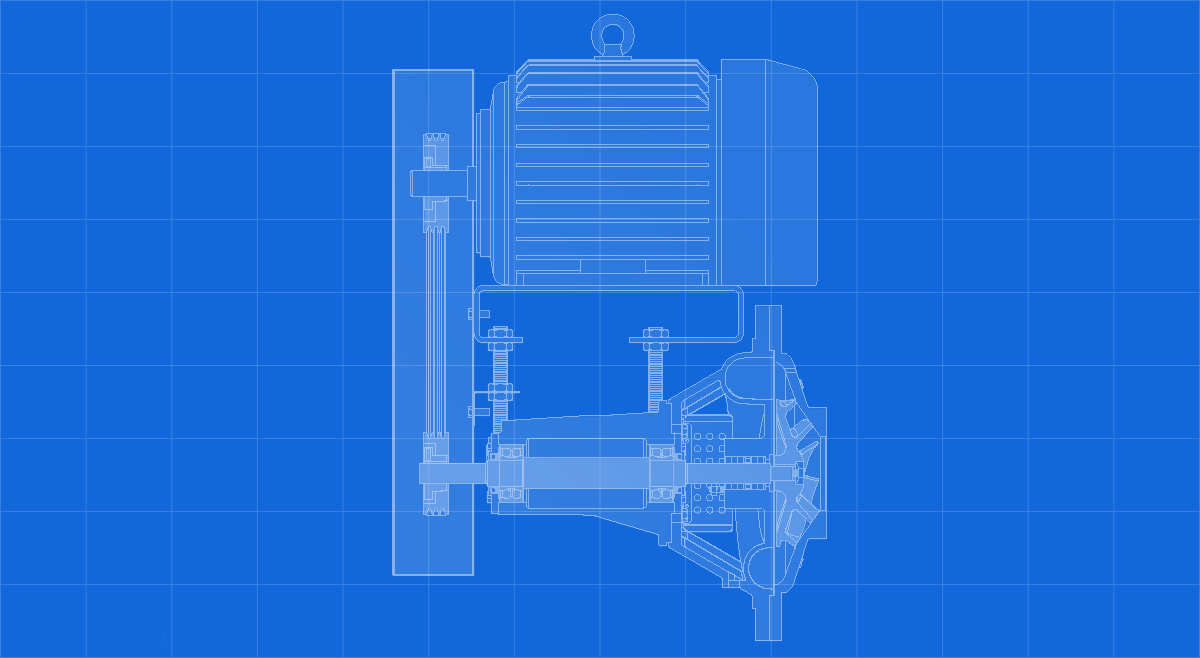

The 855 was originally developed in the late 1950s at the request of a large Original Equipment Manufacturer (OEM) of vacuum filtration equipment. Mounting the flange directly to the receiver tank eliminates suction piping and minimizes NPSH problems. The design allows pumping to resume even after short periods of interrupted flow. Capable of operating in vacuum conditions up to 26″ Hg, the specially designed semi-open impeller assures pumping from a trickle to full capacity. Rugged in design and dependable in nature, the 855 is a workhorse in some of the toughest environments in the industry.

The 855 features an overhead v-belt drive arrangement as standard, with options for close-coupled units. By utilizing either belt drive or variable frequency drive, performance characteristics can be fine-tuned to match most system requirements. With a simple, vertically-split case design, the 855 may be disassembled to expose the entire wetted area. Standard features include a packed stuffing box with seal water connections provided to ensure lubrication and eliminate vacuum/air leakage. Pumps come with discharge flanges machined for both Class 150 ANSI and DIN PN10 connections.

Corrosion-resistant shafts are used to eliminate the need for shaft sleeves. Impellers are keyed to the shaft, providing a secure fit and protection, should momentary reverse rotation occur. The swing-out mount is a popular optional feature allowing inspection of the pump and quick access to the tank interior.

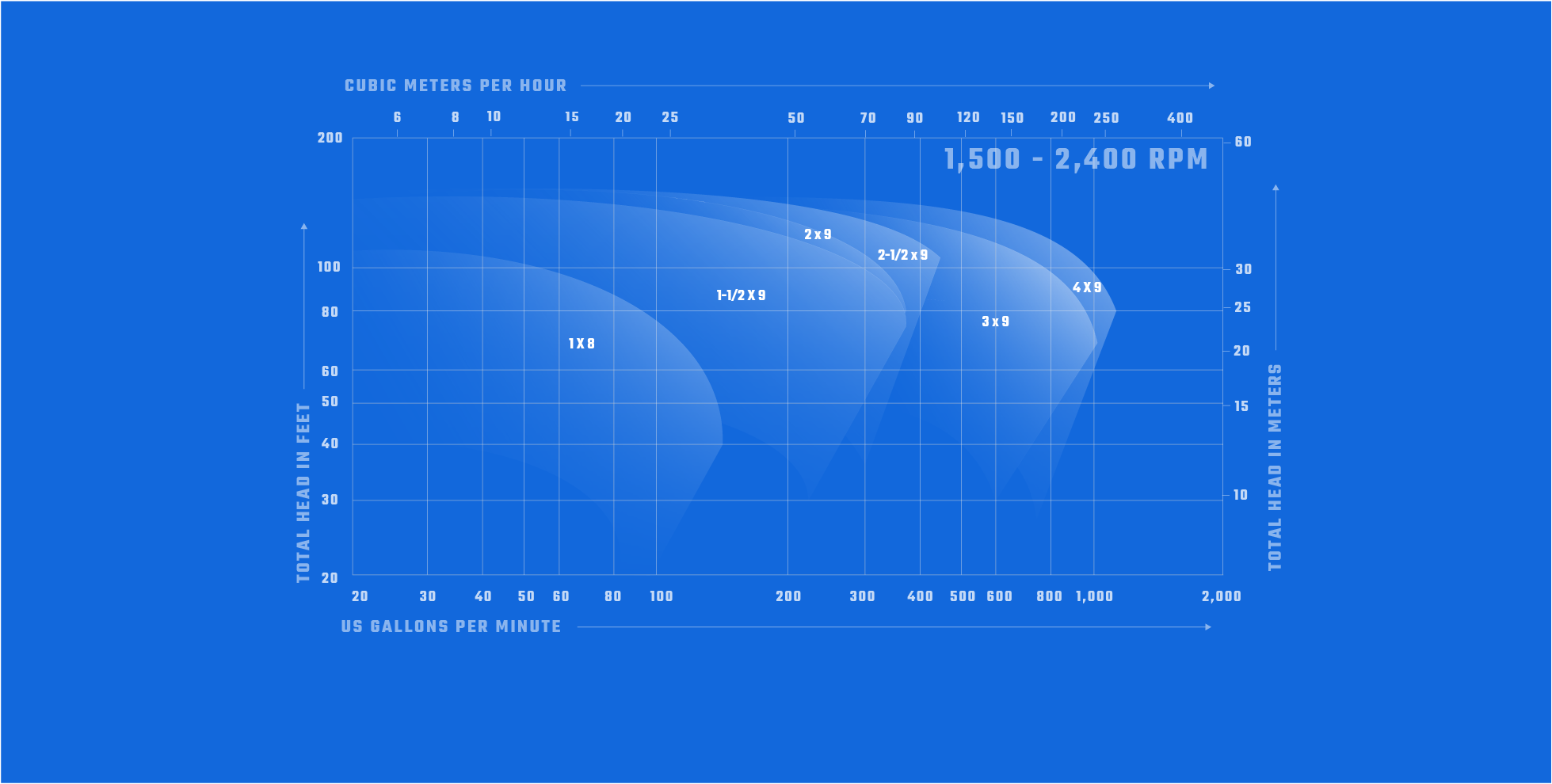

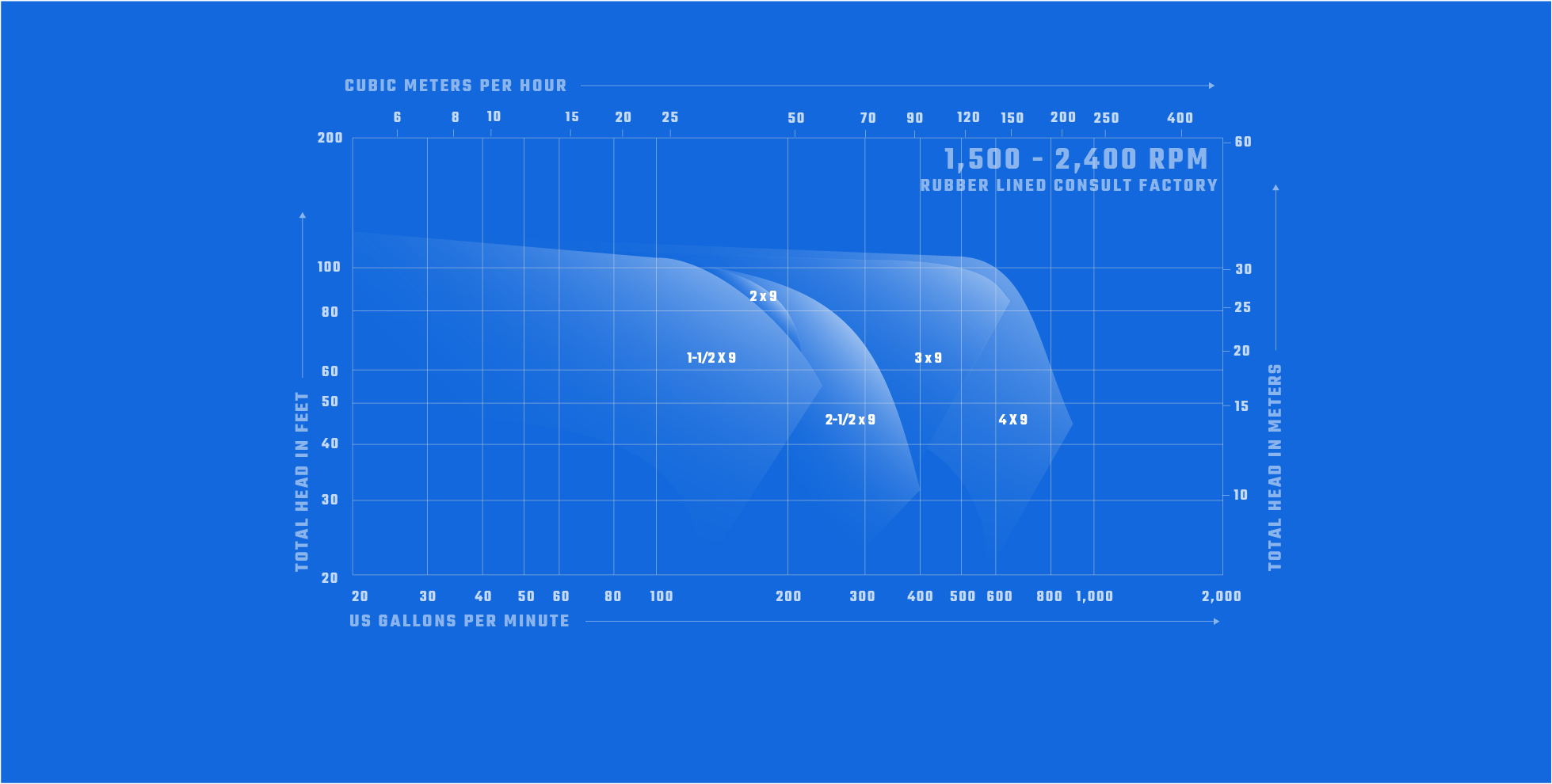

Hydraulics

Flows To

700 GPM

159 m3/hr

Heads To

120 ft.

36 m

Power To

20 HP

15KW

Speeds To

2,450 RPM

Temperatures To

250° F

121° C

Hydraulic Coverage

Specifications

Materials of Construction

| Casing | Cast Iron, CD4MCuN or Rubber-Lined |

| Impeller | Cast Iron, CD4MCuN or Rubber-Lined |

| Shaft | Duplex SS or 17-4PH SS |

| Bearing Frame | Cast Iron |

| Other materials of construction available upon request. |

Design Data

| Rotation | Counter Clockwise |

| Input Power | Up To 20HP |

| Discharge Connection | Flanged Class 150 ANSI and DIN PN10 |

| Bearings | Greased for Life |

Features

Mounting

Flange mounting directly to the receiver tank eliminates suction piping and diminishes NPSH problems. The design allows pumping to resume even after short periods of interrupted flow.

Impellers

Semi-open impellers are keyed to the shaft for secure fit.

Stuffing Box

Packed stuffing box as standard, mechanical seals are available as an option.

Bearings

Sealed-for-life ball bearings on both the inboard and outboard locations ensure a long, low-maintenance life. (Single sealed-for-life ball bearings are used on 1″ x 8″ model)

Shafts

Stainless steel shafts are used for corrosion resistance.

Belt Drive

System includes motor mounting plate, adjusting rods, belts, sheaves and guard.