Meeting the Stringent Environmental Qualification Requirements of MIL-STD-810G

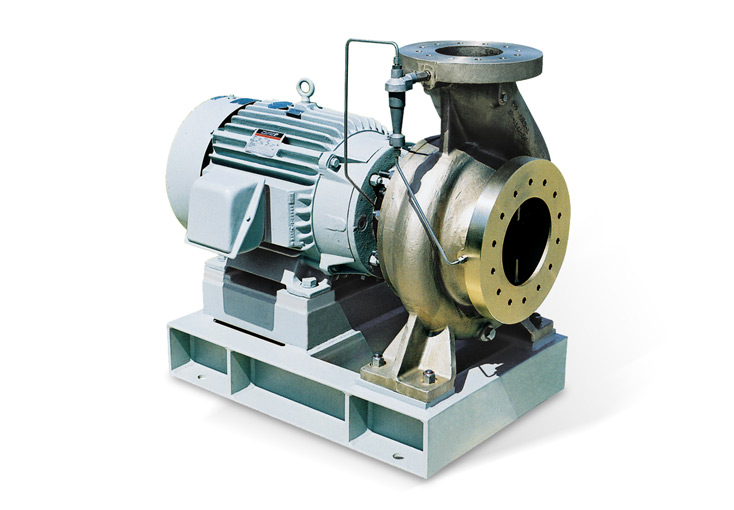

Carver Pump is one of the leading pump suppliers to the US Navy and has been providing centrifugal pumps since World War II. Carver pumps are installed on all current ship building programs (i.e., Ford Carriers, Zumwalt Destroyers, Aegis Destroyers, Littoral Combat Ships, America Big Deck Amphibious Assault Ships, San Antonio Amphibious Transport Docks and Virginia Submarines). Carver’s reputation within the Navy community over the years has led to opportunities with other branches of the armed forces, including the Coast Guard and Army. After undergoing a competitive selection process, Carver Pump was awarded a contract to replace radar cooling pumps that failed to meet reliability requirements. These pumps are used to cool the transportable radars that operate as part of the THAAD (Terminal High Altitude Area Defense) and are designed to be operated all over the world. The program is managed by the MDA (Missile Defense Agency) and the system is owned by the US Army. Reliability plus weight were the major factors in the pump selection process

More