KWP

The KWP is designed for fluids with entrained solids and fibrous materials up to 1.5″ in diameter. Wide passages in the two-vane enclosed impeller minimize clogging and crushing of the entrained material. Primarily a horizontal unit, the KWP can be either frame-mounted or close-coupled.

Common options include soft packing, single or double cartridge seals, and any type of seal flush plan.

The back pull-out design makes maintenance easy and lower total life cycle cost. Shaft deflections are limited to 0.002″ at the seal.

All together, these features combine to make the KWP a pump of exceptional value, combining affordability with some of the most efficient hydraulics found in a pump of this type.

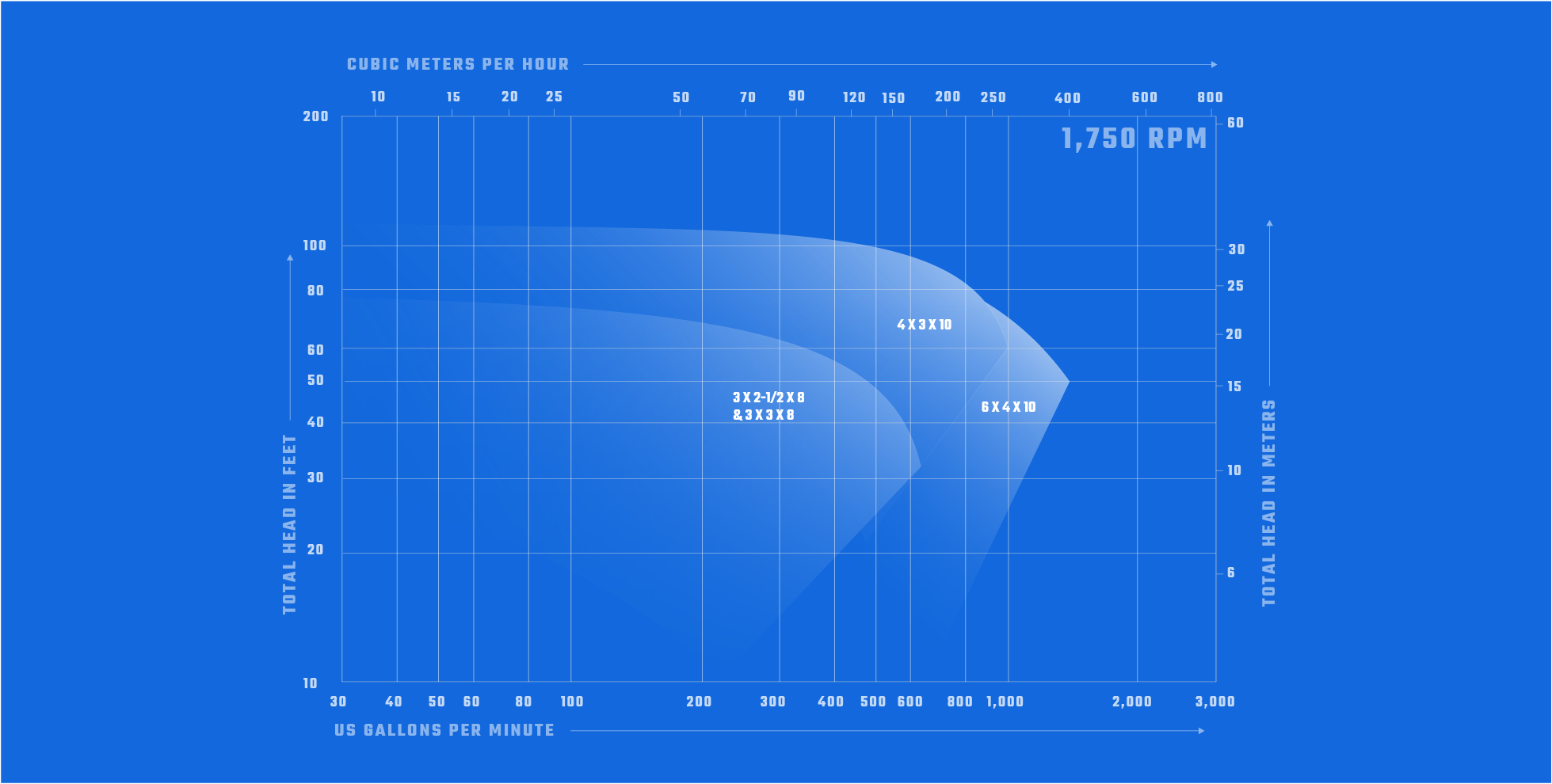

Hydraulics

Flows To

1,300 GPM

300 m3/hr

Heads To

240 ft.

100 m

Solids To

1-1/2 in. diameter

38 mm diameter

Power To

50 HP

40 KW

Speeds To

3,550 RPM

Temperatures To

250° F

120° C

Hydraulic Coverage

Specifications

Materials of Construction

| Casing | Cast Iron or 316 SS |

| Bearing Frame | Cast Iron |

| Impeller | Cast Iron or 316 SS |

| Mechanical Seal | Carbon on Ceramic or Silicon Carbide Faces |

| Shaft Sleeve | 316 SS |

| Wear Rings | 17-4PH SS |

| Other materials of construction available upon request. |

Design Data

| Input Power | Up to 50 HP |

| Configuration | Frame Mounted or Close Coupled with JM Shaft Extension |

| Connections | Class 150 ANSI Flanges |

Features

Wear Rings

Replaceable wear ring.

Impellers

Wide passages to minimize clogging and crushing of the entrained material.

360°Registered Fits

Fully confined gaskets assure proper sealing and alignment of critical fits.

Mechanical Seal

Single mechanical seal on close coupled units.

Back Pull Out Design

Allows inspection of rotating elements without disturbing the piping.