Amine Scrubbing System Overview – How Amine Treating Works

July 23rd, 2021

In the oil and natural gas industry, amine scrubbing is a necessary process. It is used in natural gas processing plants to ensure the quality of natural gas before selling or further processing.

We will also look at amine scrubbing pumps and how to select the right one.

In this article, we’re going to have an overview of the amine scrubbing system:

- What is amine scrubbing?

- Why it is important

- Which amines are used in sweetened gas

- The amine scrubbing system

- Alternative amine treating systems

- Challenges of amine treating

- Pumps for amine scrubbing

What is Amine Scrubbing?

Amine scrubbing, also called amine gas treating, gas sweetening, or acid gas removal, is the process of removing hydrogen sulfide (H2S) or carbon dioxide (CO2) from gasses.

The gas starts the process as “sour gas” and exits as “sweet gas.” It is called “sweetening” since the odor of the gas is improved without the presence of H2S.

Amine Treating – Why Carbon Dioxide and Hydrogen Sulfide Needs to Be Removed From Natural Gas

Natural gas is “sour,” meaning it contains high levels of H2S or CO2. These chemical compounds must be removed from the gas before the gas can be sold.

That is why even though hydrogen sulfide and carbon dioxide removal can cost significant amounts, it is an essential step in natural gas processing.

What are Amines?

In natural gas processing, an “amine” is an aqueous solution containing several alkylamines.

A variety of amines are used in the sweetening of acid gasses. Which amine solution is used depends on several factors.

The most common amine aqueous solutions include:

| Diethanolamine (DEA) |

| Monoethanolamine (MEA) |

| Methyldiethanolamine (MDEA) |

| Diisopropanolamine (DIPA) |

| Aminoethoxy Ethanol (Diglycolamine) (DGA) |

These liquid amines come together with the sour gas and absorb the H2S and CO2 in them.

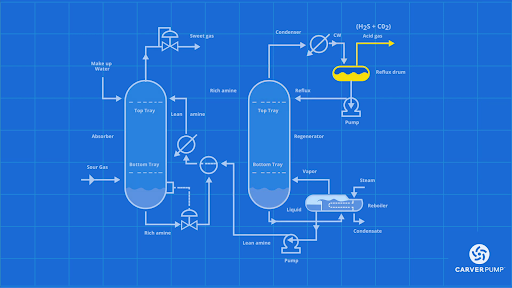

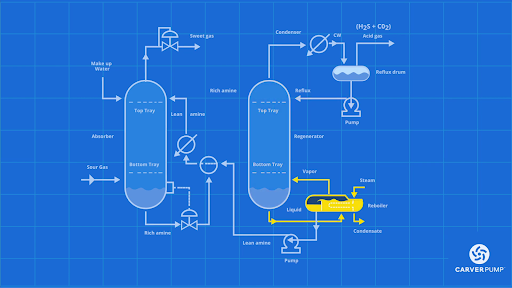

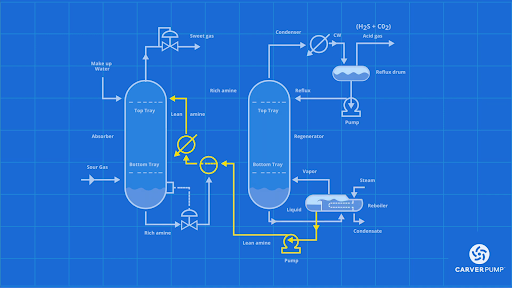

Amine Scrubbing System

In order to get rid of the H2S and CO2 in gas and prepare it for sale or further processing, the gas must go through the amine scrubbing system.

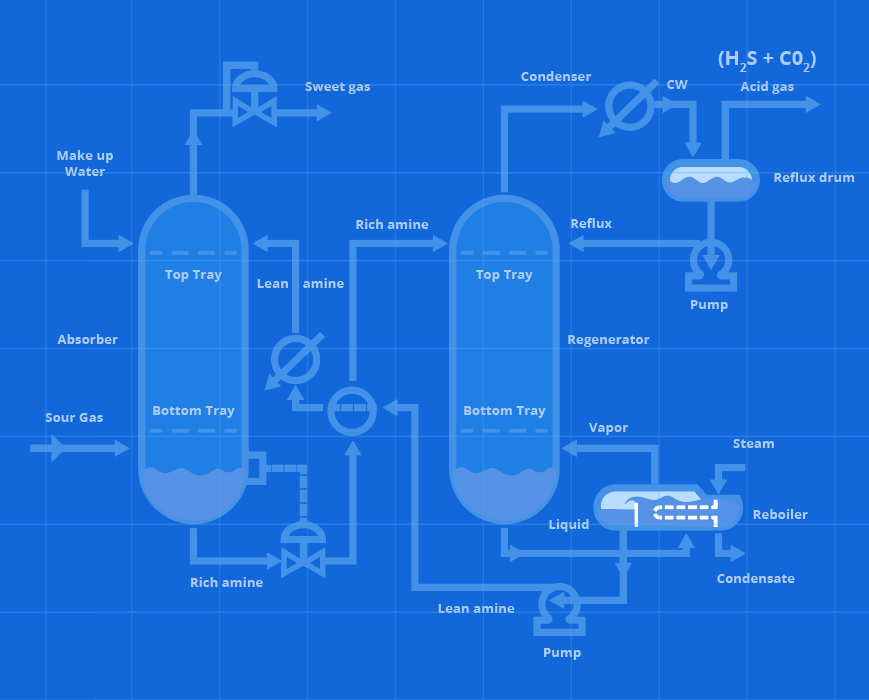

Most amine scrubbing systems have two essential processes: absorption and stripping.

Let’s have a closer look at each one.

Absorption

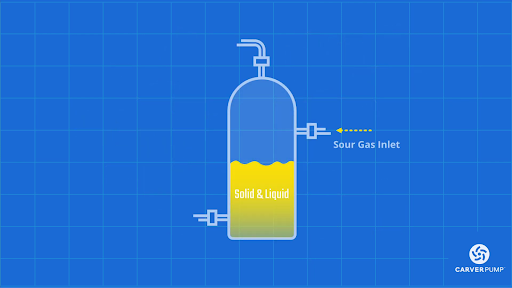

Before the gas can go through the amine scrubbing process, all solids and liquids must be removed first. That is why the first step is for the sour gas to go through an inlet separator, which eliminates both of these using baffles and mist extractors.

From there, the gas then enters the primary separator.

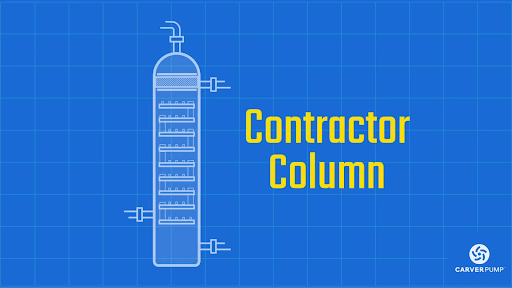

The most common design for the main separator is the contactor column.

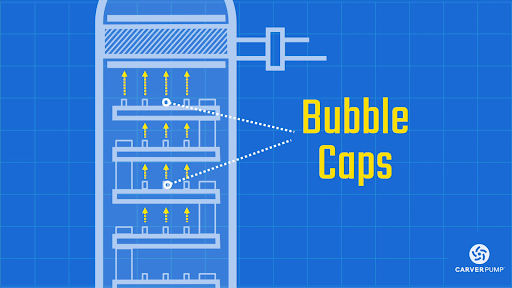

In this design, the column is separated by trays. Bubble caps on these trays allow gas to rise from tray to tray without the dropping of the liquid.

These columns also contain weirs on the sides to allow the fluids to flow downwards through the trays.

You may see how this system works in this video:

The sour gas enters the column through an inlet at the bottom, while the liquid lean amine solution enters from the top.

The inlet gas rises through the bubble caps and makes contact with the lean amine on the trays. This is when the H2S and CO2 capture happens. As the gas stream moves upwards through the trays, more and more of the excess carbon dioxide and hydrogen sulfide are caught in the amines.

By the time the gas gets to the top of the column, it goes through a mist extractor to remove any liquids. It is now sweet gas and is ready for sale or further processing.

It is important to note that the pressure within the column must be high, while the temperature is kept low. Low pressure and high temperature may increase the flow rate of the amines, making them less efficient for H2S and CO2 capture.

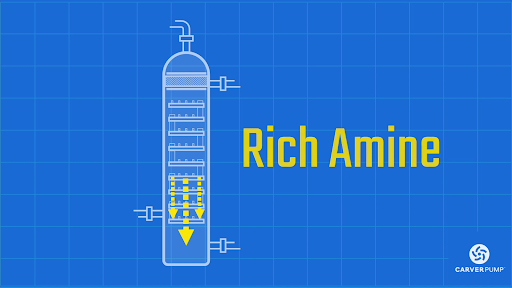

As the gas enters from the bottom of the column, the lean amine is pumped into the column from the top. These flow over the bubble caps, capture the H2S and CO2, and then flow downwards to the next trays until they reach the bottom where they are now rich amines.

Here, the now rich amine is pumped towards the stripping column, where it is treated before being pumped back into the separator column as lean amine.

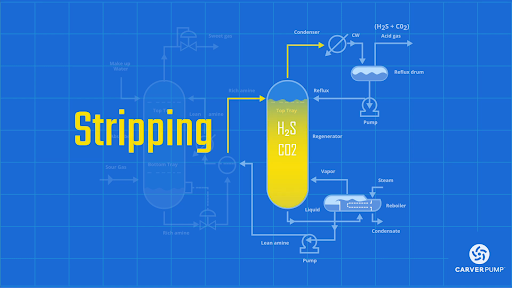

Stripping

Once the amine leaves the separator column, it is carrying absorbed acid gasses. This rich amine flow is then pumped into a stripping column, where the H2S and CO2 are stripped, and the amine can flow back into the separator column.

Advanced technologies like this are timely solutions to cut capital costs for gas processing plants. In this type of system, the amines never leave the system. They simply flow back and forth between the absorption column and the stripping column.

The temperature is kept high inside the stripping column. This helps to separate the carbon dioxide and hydrogen sulfide from the liquid amines.

In the stripping column, vapors (H2S and CO2) rise to the top, pass through a condenser, and are released as steam and acid gasses.

Meanwhile, the rich amine flows to the bottom of the column, where it is transferred to a reboiler.

The reboiler removes any remaining H2S and CO2 from the liquid before it is finally pumped back into the separator column.

Alternative Amine Treating Systems

There are several other configurations used for acid gas removal. Some of these alternative stripping configurations include:

- Matrix

- Internal exchange

- Flashing feed

- Multi-pressure with split feed

While they all follow the same process described above, there are a few differences in these systems that provide certain advantages over the standard system for certain conditions.

For example, the matrix configuration has better energy efficiency than standard amine treating systems. Due to the higher pressure inside these systems, the reboiler does not require as much energy as it would in other configurations.

Another example is the flashing feed configuration. In this system, the latent heat caused by the water vapor helps to strip some of the absorbed acid gasses from the rich amine with CO2 and H2S that is entering the separator column. By doing so, this system also helps improve energy efficiency.

There are other configurations, all of which contain tweaks to the standard system to help improve energy efficiency. These are done because energy consumption is one of the biggest challenges of amine treating. These alternative systems may also be more effective depending on what the amine unit is treating.

Challenges of Amine Treating

If oil and natural gas streams were extracted from the earth in their pure form, there wouldn’t be a need for amine systems. However, due to the presence of acid gasses like carbon dioxide and hydrogen sulfide, amine plants are needed.

Without amine plants and amine systems, the oil, gas, or liquid hydrocarbons extracted would not meet the stringent outlet gas specifications.

The presence of these sour gasses in natural gas streams and liquid hydrocarbon streams may also cause corrosion inside piping systems. This will further deteriorate the quality of gas production.

That is why even though amine systems require high operating costs, it is essential in the oil and gas industry.

The amine treating process itself also comes with several challenges, both technical and logistical.

TECHNICAL CHALLENGES

Some of the technical challenges of amine treating include:

- Difficulty in transferring carbon dioxide from the natural gas into the amine due to low pressures

- RIch amine degradation and acid buildup due to the oxygen in the acid gasses

In order for the amine treating system to work, there must be high pressure inside the columns. This is to ensure that the flow rate of the amine solution is high and steady.

Aside from that, low pressure also makes it difficult for the carbon dioxide in the unsweetened gas to bind to the amines. This makes the amines less effective at carrying absorbed acid gasses away from the oil and natural gas stream.

Another challenge is the oxygen that is sometimes present in the acid gasses, which can cause a chemical reaction. Absorption and chemical reaction of the oxygen can cause the amines to degrade, making them less effective at removing the CO2 and H2S from the sour gas.

There are several other technical challenges that come up in amine treating. The good news is that most of these challenges can be solved with a good system and a good amine treating pump (more on this below).

LOGISTICAL CHALLENGES

The logistical challenges of amine treating are perhaps more difficult to deal with. These challenges include:

- Lots of energy needed

- A good and safe location to dispose of H2S and CO2

- Big facilities

Amine treating is not a small process by any means. However, it is a process that is essential. That is why even with these logistical challenges, people in the oil and natural gas industry find solutions to each one of these – whether it’s where to find an efficient source of energy, a safe place to dispose of the H2S and CO2, and the space to build such a large facility.

Amine Scrubbing Pumps

One of the most vital components in the amine scrubbing system is the amine pump. Since amine scrubbing happens in a closed-loop system, centrifugal circulating pumps are the right choice for this operation.

How to Choose an Amine Scrubbing Pump

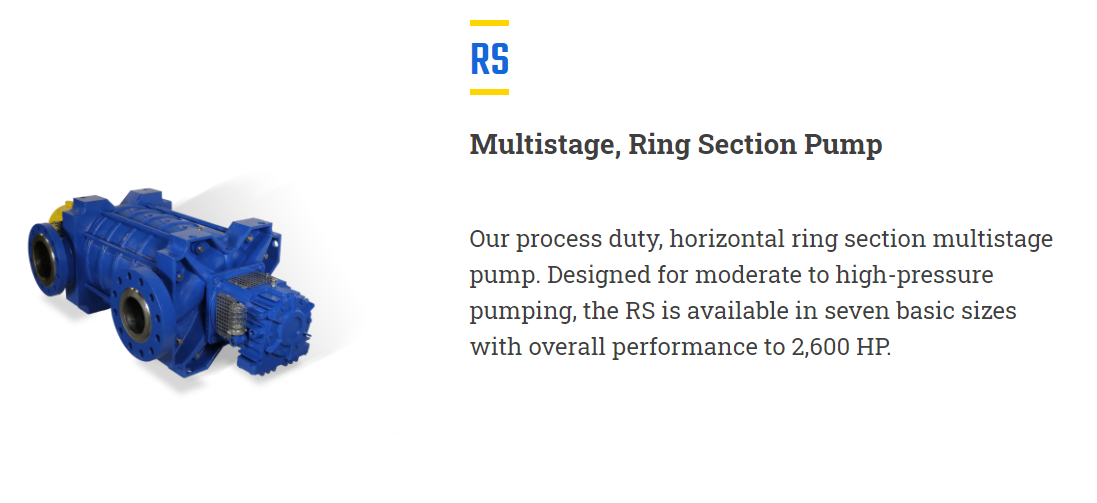

Because of the high pressure within the amine scrubbing system, a high-pressure multistage ring section pump is perhaps one of the best types of pumps for the job.

With the high pressures these pumps provide, the number of trays inside the column separator can be reduced while still maintaining the same total head required. A pump like this can provide energy-efficient solutions, cut costs, and reduce footprint.

Getting a pump from a manufacturer that is known for its quality is also critical. The cost of maintenance and repair can rack up. That is why selecting a low-quality pump to cut costs can cost you more in the long run.

A pump from a reliable manufacturer ensures that the entire process is effective, has low energy consumption, and can run for extended time periods without constant repairs.

Carver Pump RS – The Best Amine Solution Pump

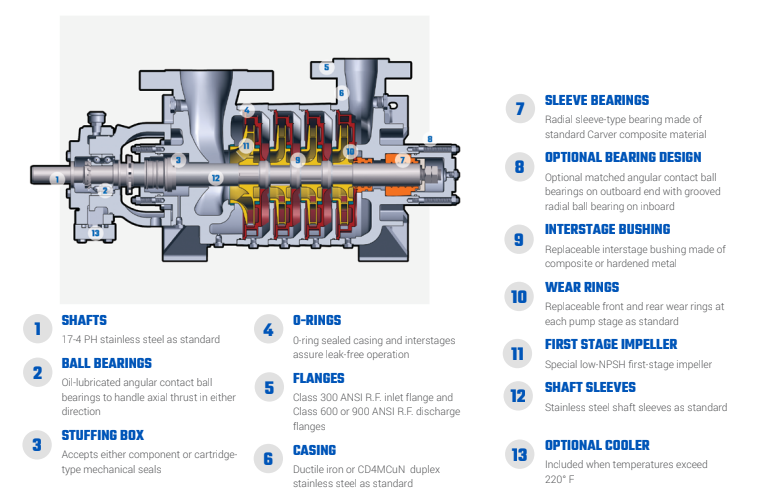

Your best option for pumping amine solutions is the Carver Pump RS.

This multistage, ring-section pump can pump flows up to 2,000 US GPM, and heads up to 3,400 ft.

With it, the footprint in your chemical engineering, natural gas processing, or power plants will be far less. Plus, the interstage diffusers minimize radical loads for longer seal and bearing life while carefully controlling fluid flow for smooth and quiet operation.

You may learn more about the RS here, or download its brochure here.

About Carver Pump

The RS is manufactured by Carver Pump, a leading company known for its high-quality centrifugal pumps.

Certified by Intertek to conform to ISO 9001:2015, all Carver Pump pumps are guaranteed to meet the highest engineering standards in the world.

Based in Muscatine, Iowa, all Carver Pump pumps are proudly American-made. Carver Pump provides world-class pumps, R&D, customer service, and continuous improvement in everything they do.

When it comes to robust technology, nobody does it better than Carver Pump. That is why for all your oil and gas applications, trust only Carver Pump!

Talk to a pump expert

+563.263.3410