Marine Oil Transfer Pumps: The Ultimate Guide

December 9th, 2020

One of the most critical pumps to have onboard every ship is the oil transfer pump.

Oil transfer is not only essential for a vessel to reach its destination, but it is also very hazardous. That is why you cannot take any chances with your marine oil transfer pump.

In this article, we’re going to have a complete look at oil transfer pumps:

- What exactly oil transfer pumps are

- The different types of oil transfer pumps

- What to look for in an oil transfer pump

- How and where to install your oil transfer pump

- How to maintain your oil transfer pump

- Best oil transfer pumps for ships

By the end of it, you’ll know everything you need to know about marine oil transfer pumps.

What are Marine Oil Transfer Pumps?

As the name suggests, oil transfer pumps carry oil and other viscous liquids. In the marine industry, oil transfer pumps are responsible for transferring fuel oil into and around your ship.

Most ocean vessels use HFO (heavy fuel oil) to power their engines. These oils initially go into the ship’s bunker tanks (found in the double bottom) from the port or bunker boat.

From there, the oil transfer pump then carries the HFO to the settling tank inside the engine room. Doing this is the primary function of the oil transfer pump.

Oil transfer pumps are also responsible for moving the excess oil in the overflow tank back into the storage tank. And can be used for draining oily bilges and moving diesel oil from tank to tank.

That’s why having reliable oil transfer pumps is critical for the marine industry. If something goes wrong, you will be in a very hazardous situation. And if your pump is inadequate, you won’t be able to fuel your ship correctly.

Types of Oil Transfer Pumps

There are several different types of oil transfer pumps you can find in ships. All of these have their own set of advantages and disadvantages.

Let’s have a closer look at some of the more popular ones.

Centrifugal Oil Transfer Pumps

Centrifugal pumps are by far the most widely-used type of pump in the world. And the same is true when it comes to moving heavy oils.

These are the most simple, easy to maintain, and affordable types of oil transfer pumps.

However, one downside to centrifugal pumps is that they need priming first. Running a centrifugal pump dry can have serious consequences, including destroying the impeller inside.

Centrifugal pumps work in a certain way that makes dry-running damaging.

How Centrifugal Pumps Work

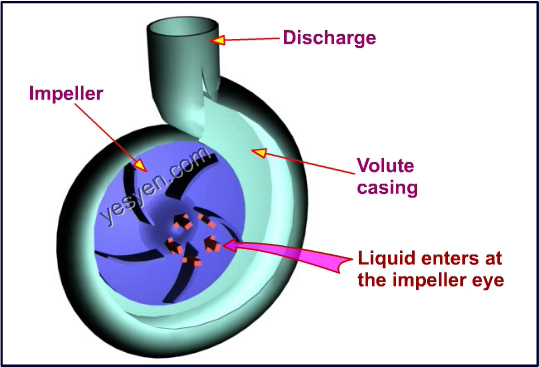

Photo from yesyen.com

Inside a centrifugal pump, an impeller spins at incredibly high speeds. Because of this, the liquid pushes to the sides of the casing and out the discharge. Once the water exits, it creates low pressure inside the pump, which pulls in more oil.

The two main components of a centrifugal pump are its impeller and the shape of its volute casing.

Speaking elementarily, the impeller is essentially a spinning disk with vanes that curve outward. As it spins, the vanes push water to the sides using centrifugal force – hence the name.

The volute casing has a snail shape, where it starts small and expands towards the exit. This design forces the water out of the discharge instead of turning the water around inside the pump.

As the oil leaves the discharge, this creates low pressure inside the casing, which pulls in even more liquid.

That’s why centrifugal pumps need priming first. If nothing exits the discharge, there won’t be low pressure inside the pump. The impeller will spin, but it won’t pull in anything. Instead, it will just circulate the air inside the pump.

But because of the way they work, centrifugal pumps can move extremely high capacities of liquid. These pumps give the highest flow rates of any type of pump.

Advantages and Disadvantages of Centrifugal Pumps

Advantages:

- High capacity

- Simple design

- Easy maintenance

- Can handle small debris

- Affordable

Disadvantages:

- Needs priming

Gear Oil Transfer Pumps

Another type of oil transfer pump commonly found in ships is gear pumps.

Gear pumps are a type of positive displacement pump. They don’t need priming, and they are also great for handling viscous liquids, like fuel oil.

However, gear pumps are more expensive than centrifugal pumps. They are also more complicated and require a lot more maintenance.

How Gear Pumps Work

Gear pumps have two gears inside a tight casing. As the gears spin against each other, this creates an expanding volume on the inlet side – where water is brought in, trapped in the gear teeth, brought around the gears, and finally squeezed out the discharge.

The gears have meshing, which doesn’t allow any fluid to pass in between them. The meshing also keeps the fluid stuck in the gear teeth as it makes its way around to the discharge side.

Because of this design, gear pumps can run completely dry with no problems. These pumps can suck fluids even without priming first.

However, since gear pumps use a very tight design, debris can easily damage the pump. Strainers or other filtering devices are needed to prevent debris from getting in.

Advantages and Disadvantages of Gear Pumps

Advantages:

- Doesn’t need to be primed

- Great for viscous liquids

Disadvantages:

- High-maintenance

- Expensive

Screw Oil Transfer Pumps

Another type of positive displacement pump used for oil transfer is the screw pump.

Screw pumps are similar to gear pumps in a lot of ways. They are great for handling high viscosity fluids and don’t need priming.

Screw pumps are also easier to maintain than gear pumps. But they are also more expensive.

How Screw Pumps Work

Like gear pumps, screw pumps work within a tight casing. But instead of gears, they have a set of screws turning and pulling water towards the discharge. This design provides several advantages over gear pumps.

Tight meshing also prevents the fluid from getting in between the screws. Like gear pumps, the liquid is forced around the pumps before getting pushed into the discharge pipe.

Screw pumps are capable of dry-running and don’t need priming. Compared to gear pumps, they’re quieter, have higher efficiency, and don’t need as much maintenance.

However, screw pumps are also more expensive, and if there is damage, you’ll have to replace the entire screw.

Advantages:

- Doesn’t need to be primed

- Great for viscous liquids

- Quieter and more efficient than gear pumps

Disadvantages:

- Expensive

- Costly maintenance

How to Choose a Marine Oil Transfer Pump

There is no one-size-fits-all when it comes to oil transfer pumps. Every ship has its own set of needs.

So how do you choose the right oil transfer pump for your ship?

First and foremost, a pump that is ABScertified will better assure compliance with local or regional certification requirements. Using a pump with these certifications ensures that you are complying with international maritime standards and regulations.

Aside from that, there are several other things you need to consider.

What Type of Oil Transfer Pump Do You Need for Your Ship?

Centrifugal, gear, and screw pumps are the most commonly used oil transfer pumps in ships. And for a good reason, these three types get the job done very well.

Of the three, we most commonly recommend using a centrifugal pump.

Centrifugal pumps are popular because they have the highest capacity of all types. In large ships, where you have to move a lot of oil, an excellent centrifugal pump will meet your high capacity demands.

Centrifugal pumps are also a lot easier to maintain. They don’t require nearly as much maintenance as other types – where the tight casing can quickly get damaged. The simple design of centrifugal pumps also makes replacing parts and minor fixes simple.

Finally, centrifugal pumps cost less upfront than other types. Spare parts and repairs are also not as costly as they are for positive displacement types.

How Much GPM Do You Need From a Marine Oil Transfer Pump?

GPM, or gallons per minute, is the measurement of your pump’s capacity. It tells you how much fluid your pump can move every minute.

When it comes to GPM, there is no perfect amount for oil transfer. The right GPM depends on how big your tanks are. The more GPM you have, the faster your pump can fill up your tanks.

Generally, you’ll want the highest GPM you can get that’s reasonable. You want a pump that can move oil to the settling tanks quickly. But you also have to consider the space in your ship’s engine room.

How Much Head do You Need from an Oil Transfer Pump?

You can determine how much head you need from your oil transfer pump by considering the elevation, friction loss, and pressure of your pipes.

Once you determine those, you can use the following formula to calculate how much head your pump needs:

Elevation + friction loss + pressure = total head

Elevation refers to the vertical rise of your pumps. If the end of the discharge pipe is 20 feet above the pump, your elevation is 20 feet (regardless of the pipe’s horizontal length).

Pressure refers to the amount of pressure in the fluid in the pipes. Since we are talking about oil pumps, this will be higher than that of water pumps. Once you measure the PSI, convert it to head feet with this formula: 1 PSI = 2.31 head feet.

Friction Loss refers to the amount of flow loss due to the friction between the fluid and your pipes. It’s best to use an online calculator to identify your friction loss since the equation is complicated.

Keep in mind that oil is calculated differently from water, so make sure your calculator allows you to choose the fluid type. Oil may have higher head requirements depending on its specific gravity when you are pumping into (or from) a pressurized vessel.

With that equation, you can calculate how much head you will need from your pump.

How to Install a Marine Oil Transfer Pump

When installing an oil transfer pump into your ship, there are several things you need to know. These will ensure that your pump will work as effectively and efficiently as possible.

Below are some of the most important things to be aware of when installing a marine transfer pump.

Oil Transfer System in Ships

As said before, your ship should have several tanks for your fuel oil. The most common design is to have a storage or bunker tank, a settling tank, a service tank, and an overflow tank.

Bunkering, the process of loading the ship with fuel, is done on the deck. Ocean vessels need a lot of stored fuel for the long journey ahead. This fuel first goes into the storage tanks usually found on the double bottom of the ship.

The storage tank has heating coils that ensure the oil remains at the right viscosity for pumping around the ship. HFO must be at around 40 degrees celsius for pumping.

Before making its way to the settling tanks, the fuel passes through a filter that removes any oil debris. HFO and other fuels in the bunker tanks often have metals and other particles that should not get into the engine.

The purpose of the settling tank is to separate the water from the oil. Water settles at the bottom of the tank, where it eventually leaves the tank before a pump finally brings the fuel to the service tank.

When oil gets to the service tank (via centrifuges), it is already cleaned entirely before heading into the engine. Supply pumps and booster pumps then take the oil from here and inject it into the engine at the right pressure.

Another component of the oil transfer system is the overflow tank. Oil transfer systems should shut off the pump automatically whenever tanks fill to a certain level. However, because of the hazardous nature of oil spills, you cannot take chances.

That’s why every tank should have a connection to the overflow tank. Should any tank (storage, settling, or service) fill above its maximum level, an alarm will go off, and the excess oil will flow into the overflow tank – preventing oil spills within the ship.

How Many Oil Transfer Pumps Do You Need on Your Ship?

Depending on the design, you may only need one main oil transfer pump to bring the oil from the storage tanks to the settling tank. This same pump can also suction from the overflow tank, oily bilge tanks, diesel oil storage tank – and discharge to the storage tanks, oily water separator, and diesel oil service tank.

A high capacity centrifugal pump can handle all the oil transfer needs in a ship. However, if you have multiple large tanks, you may use two or more pumps.

Your oil transfer pump should have an elaborate piping system that connects to various tanks, including the diesel oil tank. Valves then control where the suction comes from and where to discharge.

Marine Oil Transfer Pump Alarms and Switches

Oil transfer is an essential task in every ship, yet at the same time, it is also very hazardous. That is why you should have automatic alarms and switches.

Each tank should have a low alarm and a high alarm. The low alarm signals that the tank needs more oil. These are present in both the settling and service tanks.

The high alarm and switch are for when the tank is about to overflow. This alarm should switch off the oil transfer pump. If not, the alarm will go off, alerting the engineers on board to shut the pump off as the excess oil flows into the overflow tank.

Even with automatic switches, it is essential to have manual controls as well. It is also vital to have a way to switch off the pump from outside of engine spaces. If a dangerous situation arises, such as an oil spill or fire, you can stop the oil flow from a safe place with the emergency switch.

Marine Oil Transfer Pump Pipes

Pipes for oil transfer generally fall under one of two categories: low-pressure and high-pressure lines. When the HFO moves from the storage tank to the settling tank, you don’t need high-pressure (unlike when the fuel injects into the engine), which is why low-pressure pipes carry the oil there.

For safety purposes, these pipes should navigate away from hot areas as much as possible. Even if a line is low-pressured, this does not mean oil will not spray from a crack. That is why these pipes should never go above hot areas. It’s also a good practice to tape the flanges of these pipes.

As mentioned above, a filter also needs to be installed in the storage to settling tank’s pipe. This filter will remove any debris and metals from the oil before it gets into the settling tank.

HFO in the bunker tanks still has impurities in it. And filtering out these is one of the first steps in cleaning the oil and getting it ready for the engine.

How to Prime a Marine Oil Transfer Pump

As mentioned above, centrifugal pumps cannot run without priming. Whenever you install a new oil transfer pump, or the pump is empty, you need to prime it first.

Priming a centrifugal pump is easy. The actual operation will differ from model to model, but they generally follow the same necessary steps:

- Close discharge valve

- Open top vent

- Open outside supply line to start filling the pump

- Wait for the fluid to reach the top vent

- Close top vent

- Close supply line

Oil is generally lighter than water. That is why when priming an oil pump vs. a water pump, the NPSH (net positive suction head) will be higher and, therefore, easier to pull the fluid into the pump.

However, since oil transfer pumps deal with hazardous fluids, it’s good to have an automatic priming system instead of a manual one.

Some centrifugal pumps are self-priming. These pumps have two modes: priming and pumping.

On priming mode, the spinning impeller creates a vacuum that pulls in air and pushes it out the discharge (instead of spinning it around the casing as regular centrifugal pumps would). The flow is relatively low, but priming mode allows centrifugal pumps to fill up without engineers having to prime it manually.

Once the pump is full of liquid and no air is left, you may switch it to pumping mode. In this mode, the pump returns to its high-capacity flow. It cannot pump air anymore, but it doesn’t need to anymore since it is already full of liquid.

If your pump is not self-priming, you may also use vacuum pumps or ejectors to assist with the priming. These priming devices connect to the pump and pull in the fluid to fill up the pump. Once it is full, you may turn on the centrifugal pump.

Again, oil is a dangerous fluid to handle, especially within the engine room where the transfer pump is. Vacuum pumps or ejectors allow priming without anyone having to be at risk.

Marine Oil Transfer Pump Maintenance

If you are using a gear or screw pump, there is a lot of maintenance work needed. Centrifugal pumps don’t need as much maintenance. But just like every other machine, they still need some regular maintenance work.

Even though centrifugal pumps last long, daily checks ensure that nothing catastrophic happens on the ship.

Here are some of the regular checks and maintenance work that you should do:

Visual Check – When making engine room rounds, inspect the transfer pump visually for any abnormalities.

Temperature Check – Take a temperature reading to see whether or not the fluid in the pump is at the right temperature.

You should also check the temperature of the motor driving the pump. An increase or decrease of temperature here shows that there is something wrong with the pump-motor assembly.

Current Check – It’s also a good idea to monitor the amperage of the motor. It’s one way to spot problems with the pump.

Sound Check – Knowing what the oil transfer pump sounds like when properly working is a must. This way, any abnormal sound can be detected immediately, preventing more significant problems from arising.

Pressure Check – It’s also essential to ensure that your pump runs at the right pressure at all times. An increase or drop in pressure signals that there may be a problem. Check the valves, the filter, and look for leaks.

Vibration Check – Pumps must run as smoothly as possible. Should you discover vibration in your pump, this may mean that there is a problem with coupling, foundation, bearing, etc. – or it may mean your pump is misaligned.

It’s also a good idea to have monthly checks on the coupling alignment and foundation bolts, even without any vibrations. You should also grease the coupling to prolong its lifespan.

Filter Check – It’s good practice to clean out the oil transfer filter regularly. Debris may clog the filter eventually, which will lead to difficulty pumping in oil from the storage tanks.

Running Hours Check – Mechanical parts in pumps need replacing when their running hours are up (even if they are still working). Monitoring the running hours of all your oil transfer pump’s parts is essential to a safe voyage. A good oil transfer pump manufacturer will ensure that getting all the spare parts you need is easy.

Oil transfer in ships is one of the things you can’t afford to go wrong. That’s why checking to make sure everything is properly working is critical for every voyage.

The Best Marine Oil Transfer Pumps

When it comes to oil transfer in ships, you cannot take chances. If one thing goes wrong, this can spell doom for the entire boat out at sea.

Depending on your specific needs, there are several great pumps you can get. One of these is the GH, which is an ABS certified certified centrifugal end-suction pump.

If you’re looking for a vertical sump pump, the G2C is one of your best options.

Finally, if you need a self-priming pump for the suction lift, you should check out the self-priming KEF series

Whatever you’re looking for, make sure you get a pump that is high-quality from a company you can trust.

If you need the best and most reliable marine oil transfer pumps, go for Carver Pump.

Carver Pump is a leading manufacturer of centrifugal pumps for oil transfer. All our marine pumps are ABS certified – ensuring that our pumps meet international standards and regulations.

Carver Pump takes the time to work with you and understand your needs fully. This way, we can custom engineer and build marine pumps that will stand up to all of your demands.

Based in Muscatine, Iowa, all our pumps are proudly American made. Carver Pump’s quality management system is certified by Intertek to conform to ISO 9001:2015. Our commitment to quality includes not only our hardware, but also superior customer service, leading-edge R&D, and continuous improvement in everything we do.

The ocean is not the place to find that your marine pumps don’t cut it. Trust your shipboard services to Carver Pump, the industry leader in shipboard centrifugal pumps.