Marine Potable Water Pumps: The Ultimate Guide

December 24th, 2020

Voyages across the ocean can take weeks to complete. And with no connection to land, there is no way for these ships to buy more freshwater once they run out.

That’s why many ships have a system for producing fresh water and drinking water. And at the center of it is the potable water pump.

In this article, you’ll get a closer look at potable water pumps:

- What exactly potable water pumps are

- How ships produce potable water

- How potable water pumps work

- How to choose a potable water pump

- How to install a potable water pump

- How to maintain a potable water pump

- The best marine potable water pumps

Potable water pumps and operations vary greatly from ship to ship. This article will teach you the process and requirements for one of the most straightforward systems there is.

Let’s get started.

What are Marine Potable Water Pumps?

Potable water pumps are the driving force of a ship’s drinking water supply. It connects to a complex system that converts seawater into freshwater.

Potable water pumps, also known as the freshwater pumps, carry the freshwater from the freshwater generator to the freshwater tanks. Then from the freshwater tanks to the hydrophore tanks, which take the water to various access points onboard.

The Department of Transportation has strict regulations on the drinking water on ships. One requirement is that drinking water must be separate from the freshwater used for other onboard applications.

That is why there are at least two freshwater tanks and hydrophore tanks, one for drinking water and the other for general use.

How Ships Produce Drinking Water

The process of converting seawater into water that is safe to drink is a sophisticated one. There are several processes and filters that the water must go through before it is safe for consumption.

Converting Seawater into Freshwater

The first process is to remove the salt from the water. Ships either use distillation in the freshwater generator or reverse osmosis to do this.

Distillation

Distillation is the more common practice on ships. Freshwater generators are large machines that separate the salt and other minerals from seawater by evaporation and condensation.

The concept of freshwater generators is simple, but the mechanics of it are quite complicated.

Freshwater generators use a heat plate to evaporate the salt water. The engine jacket water heats this plate to around 80-degrees Celsius.

Since water at sea level evaporates at 100-degrees Celsius, the engine jacket water would not be enough to evaporate the saltwater in normal conditions.

That is why ships use an ejector to bring down the freshwater generator’s atmospheric pressure – the lower the pressure, the lower the boiling point of water.

Once boiled, the vapor rises through a filter mesh into the condensation compartment while the leftover salt brine goes overboard.

As the vapor rises, it comes into contact with the seawater pipe (as it pumps more seawater into the evaporator). It then condenses and is pumped to the salinometer and into the potable water pump’s freshwater tanks.

Freshwater generators have an extremely efficient design – heating and cooling the seawater using water from the engine jacket and the seawater suction pipe.

Reverse Osmosis

The other method for removing salt from seawater is through reverse osmosis.

Reverse osmosis uses special membranes to remove the salt and other minerals from seawater. The water is forced into these membranes by a pump and comes out pure on the other side.

Reverse osmosis is the more straightforward, more modern way of converting seawater into freshwater. However, it isn’t as common in ships as freshwater generators are yet.

Converting Freshwater Into Drinking Water

When the water leaves the freshwater generator, it is free from salt and minerals. It is now ideal for engine cooling, boiler feed, showers, and other applications.

However, water directly from the freshwater generator is not suitable for drinking. Without any minerals on it, it will be completely flat and acidic. Plus, there may still be some bacteria left behind on it.

Because of this, ships use a separate tank for general freshwater use and drinking water use. Cleaners, such as chlorine tablets, are sometimes added to the drinking water tank to kill microorganisms in the water.

The drinking water tank connects to a hydrophore, which uses compressed air to keep the entire drinking water system at the right pressure. It’s what ensures flowing water whenever you turn on a tap.

But before getting to the tap or drinking fountain, the water has to pass through a mineralizer and a UV sterilizer first.

The mineralizer adds trace amounts of calcium, magnesium, potassium, and carbon. Human bodies need these minerals from water to replace the minerals we lose when we sweat. These minerals also help neutralize the acidity of the water.

From there, it makes its way to the UV sterilizer. The UV sterilizer uses radiation to eliminate any remaining bacteria in the water.

By the time the water ends up in the drinking fountain, it is entirely safe to drink.

How Potable Water Pumps Work

The driving force of the entire potable water system is the potable water pump. Pumps carry the water from the freshwater generator to the tanks and then from the tanks to the hydrophore.

The most common type of pump for potable water is the centrifugal pump. Centrifugal pumps have the highest capacities, are affordable, have a simple design, and are easy to maintain.

In the most straightforward way to put it, centrifugal pumps work by using a spinning impeller inside a volute casing.

The spinning impeller has vanes curving outwards, which uses centrifugal force to fling any incoming water to the casing’s sides. The shape of the volute casing starts narrow and grows wider towards the exit. This design forces the water out of the discharge instead of spinning the water inside the pump.

As the water leaves the discharge, this creates low pressure inside the pump, which pulls in more water.

Because of the way they work, centrifugal pumps can’t run dry. They need priming first before they can operate. You have to fill the pump up with water before it can move any water.

If you let a centrifugal pump run dry, this can damage the pump or even destroy it.

How The Hydrophore Works

The job of the hydrophore is to maintain the ideal pressure in the freshwater lines. This way, there will always be a steady flow of water without switching on a pump every time water is needed.

The hydrophore tank uses compressed air to create pressure in the line. As water leaves the pipes and as the water level on the tank drops, this pressure also drops.

When the water reaches a certain level, a sensor signals the potable water pump to switch on and begin refilling the hydrophore tank. Once this happens, it increases the pressure again and allows everyone on board to enjoy a steady stream of fresh water.

The general freshwater line and drinking water line both use hydrophore tanks. After the water leaves the hydrophore for the drinking water, it first passes through a mineralizer and a UV sterilizer before reaching the tap.

How to Choose a Potable Water Pump

When looking at the potable water system as a whole, it’s easy to get caught in the workings of the freshwater generator or the hydrophore. They do all the exciting work.

However, never forget the importance of the potable water pump. It’s only task is to deliver water, but the whole system wouldn’t work without it.

That’s why selecting the right potable water pump is critical.

What Requirements Are There for Marine Potable Water Pumps?

Because of the dangers of contaminated water, your potable water pump must comply with local regulations.

The standards for potable water pumps vary from state to state, so check your local NSF standards to ensure that your pump fits the requirements.

One regulation you might need to be aware of is NSF/ANSI 61. NSF/ANSI 61 is the only American standard that deals with drinking water components and their effects on human health.

NSF/ANSI 61 inspects and has requirements for:

- Pipes and related products

- Protective and barrier materials

- Joining and sealing materials

- Process media

- Mechanical devices

- Mechanical plumbing devices

- Potable water materials

Meeting this standard ensures that the potable water on your ship is entirely safe to drink.

How Much GPM Do You Need From Your Potable Water Pump?

GPM, or gallons per minute, refers to your pump’s capacity (how fast it can pump water). How much flow you will need depends on how much freshwater you need on your ship.

Ships typically require around 15-50 tons (about… 3,000 – 11,000 gallons) of fresh water per day. Some types of ships require even more than that.

Knowing how much water your ship requires will help you select the right GPM from your potable water pump.

As a rule of thumb, choose a pump with a capacity high enough to ensure constant flowing water. You don’t need the most massive pumps for potable water use, but you certainly don’t want one that is too small to keep up.

How to Calculate How Much Head You Need From Potable Water Pumps

Aside from the GPM, it is also essential to consider the total head of your pump.

Unlike positive displacement pumps, which don’t have trouble pumping water up vertically, the flow of centrifugal pumps slows down as pressure increases. Ensuring that your pump has enough head for your use is vital.

To calculate how much head you need, add your system’s elevation, pressure, and friction loss.

Elevation + friction loss + pressure = total head

Elevation refers to the vertical rise of the water from the pump to the discharge point. It does not take into account the horizontal distance. If your fresh water storage tank is 30 ft above your freshwater generator, the elevation is said to be 30 ft.

Friction loss refers to how much flow the water loses due to friction with the pipes. There is a complicated equation used to calculate this. You may utilize an online calculator to find how much flow you lose due to your pipe’s friction loss.

The pressure is the amount of pressure that is in the pipes. 1 Psi = 2.31 head of feet.

Add those numbers together, and you’ll find out what the minimum total head required for your system is.

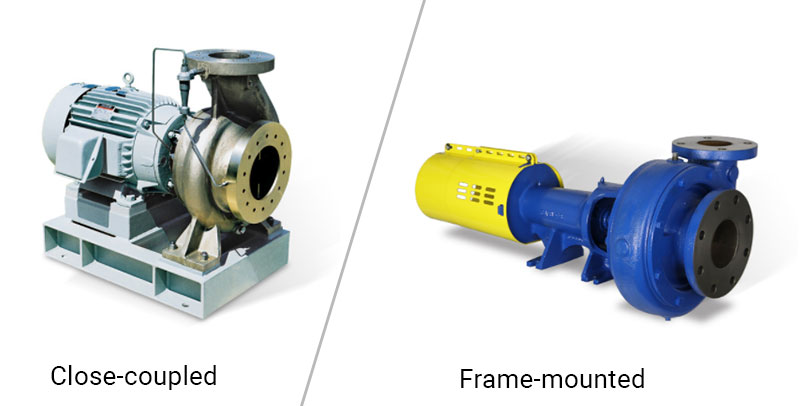

Frame Mounted vs. Close Coupled

Another factor to consider when choosing a potable water pump is whether you should get a frame-mounted or close-coupled pump.

Frame-mounted pumps are often larger and move a lot more water than close-coupled pumps.

They mount to a frame along with the motor they use. A flexible coupling connects the motor shaft and the pump shaft. A bearing frame allows the bearings to take axial and radial loads, prolonging their life.

On the flip-side, close-coupled pumps use a single motor shaft that drives all rotating elements in the pump’s wet end. Because there are no couplings, these pumps are cheaper and smaller, and they do not need aligning.

However, close-coupled pumps may not pump at the same capacities as frame-mounted pumps.

Choosing the right one once again depends on your specific situation. Because of horsepower limitations on close-coupled pumps, you may want to consider a frame-mounted pump first if you have high flow needs. For space-saving requirements, close-coupled pumps will serve you well.

How to Install a Marine Potable Water Pump

One of the last things you want onboard is for crew members to fall ill due to contaminated water. That is why installing your marine potable water pump the right way is essential for a safe voyage.

Marine Potable Water Pump Safety Standards

While freshwater pumps are perfect for other uses, the drinking water pump is only for pumping pure water. Strictly separating the two ensures that there is no cross-contamination, and the water is safe to drink.

To further protect the water from dirt or solids entering, you may install filters at the pump’s suction end. Be sure to clean these filters regularly to prevent solids from building up.

The pipes of the pump should also have non-return valves. This way,

no water will flow back and mix with water that is not safe to drink.

Furthermore, having an emergency potable water pump around will ensure a drinking water supply even if the primary pump runs into problems. If you have two pumps, alternating usage between the two prevents microbes from building up in stagnant water.

How to Prime a Marine Potable Water Pump

Centrifugal pumps cannot pump water without being primed first. Because of this, you have to fill the suction line and pump with water before they can begin operation.

If there is air inside the pump as it operates, this can cause problems in the line and in the pump itself.

Avoiding air in the line is another reason to use non-return valves. Since the potable water pump runs automatically whenever the water on the hydrophore drops to a certain level, it needs to be ready to run at any time. The non-return valves ensure that once you prime the pump, it will stay primed unless drained.

The exact process of priming a centrifugal pump will differ from manufacturer to manufacturer, but they generally follow the same steps:

- Close discharge valve

- Open top vent

- Open outside supply line to start filling the pump

- Wait for the fluid to reach the top vent

- Close top vent

- Close supply line

You may also use a self-priming centrifugal pump.

Self-priming centrifugal pumps have two modes – priming and pumping. During priming mode, the pump works like a positive displacement pump and can discharge air in the pump instead of swirling it around the casing. However, it can only run at a low capacity.

Once the pump is full of water, you may switch to pumping mode, which delivers the high flow rate that is a significant feature of centrifugal pumps.

How to Maintain a Potable Water Pump

Potable water pumps require the same maintenance checks that every other pump onboard has. Additionally, the drinking water system also needs cleaning now and then to prevent solids and bacterial build-up.

Visual Check: When doing the daily rounds, be sure to look for any visible abnormalities in the potable water pump.

Temperature Check: Check for any abnormal rise in temperature in the pump’s bearings and the motor.

Sound Check: Listen for any abnormal sound coming from the pump. Rattling sounds may indicate loose parts in the pump.

Vibration Check: Potable water pumps should run smoothly. If you notice unusual vibration, inspect for problems.

Pressure Check: A pressure drop may indicate a leak in the line. Because potable water is for consumption, this can be a severe problem.

Power Reading: Check the amperage of the pump’s motor at least every week. You can spot problems early on if you discover abnormalities here.

Filter Check: Make sure to clean out the filters and or strainers in your pipes. You may find debris building up here.

Coupling Check: If using a frame-mounted pump, check the alignment of the coupling monthly. Greasing the coupling at this time is also a good idea.

Foundation Check: Check if the foundation bolts are secure once in a while to prevent vibration.

Tank Cleaning: To ensure quality drinking water, clean out the drinking water tank with 50ppm chlorine solution at least once a year. Follow cleaning guidelines for drinking water tanks to avoid contamination.

Running Hours Check: Mechanical parts have a set lifespan. By the time a part’s running hours are up, you should replace it even if it is still functioning. A good potable water pump will ensure that getting replacement parts will be super easy.

If something goes wrong in the drinking water line, it can cause the entire ship to go ill. That is why ensuring that everything in the drinking water system is working well is critical.

Best Marine Potable Water Pumps

Potable water pumps don’t stand out when looking at the drinking water system. Yet without a reliable potable water pump, a ship cannot produce drinking water.

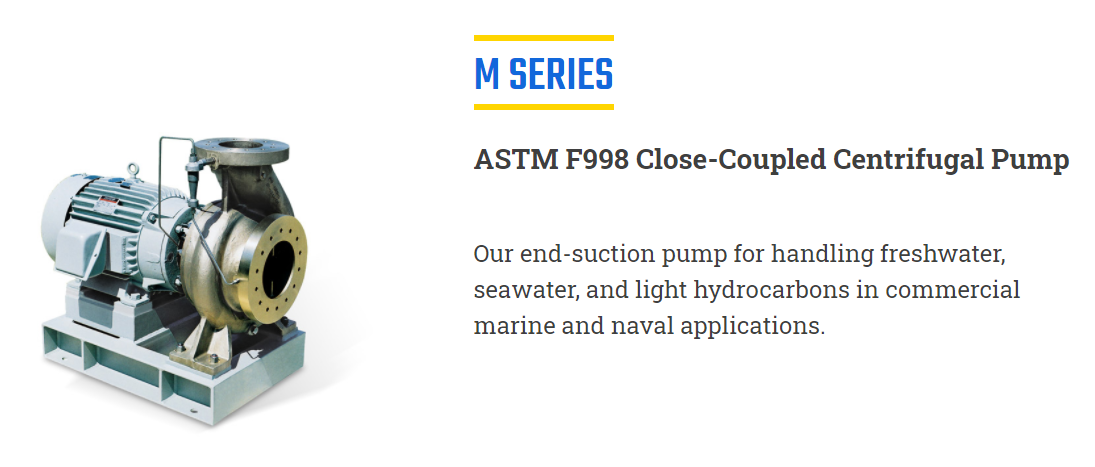

Depending on your specific needs, there are several excellent pumps you can get. One of these is the M Series, a close-coupled end suction centrifugal pump.

Despite being a close-coupled pump, the M Series can deliver very high flow rates – up to 5,000 GPM and heads up to 700 ft.

Another great option is the GH pump, which comes in both frame-mounted or close-coupled options, and is available in 28 sizes.

Finally, if you need a pump to handle high-pressure requirements, the RS multistage ring section pump is the best one for the job.

Whatever your pump needs are, you should look for a world-class manufacturer. This way, no matter how challenging the job is, you can rest assured that you will get a high-quality and reliable pump.

Speaking of manufacturers you can trust, there is no better company than Carver Pump.

Carver Pump is one of the leading manufacturers of potable water pumps. With pumps that are ABS certified, you can be sure that these pumps comply with national and international maritime standards.

Based in Muscatine, Iowa, all Carver Pump pumps are proudly American made. Carver Pump’s quality management system is certified by Intertek to conform to ISO 9001:2015. Our commitment to quality includes not only our hardware, but also superior customer service, leading-edge R&D, and continuous improvement in everything we do. Carver Pump takes the time to understand your needs and provide you with the best for every use.

The ocean is not the place to find that your marine pumps don’t cut it. Trust your shipboard services to Carver Pump, the industry leader in shipboard centrifugal pumps.