Protecting Your Pump Against Low to No-Flow Conditions

July 7th, 2020

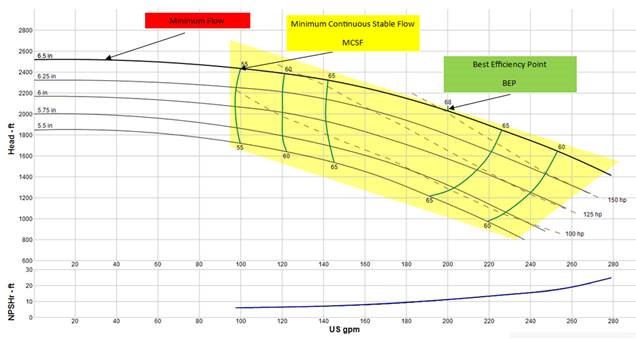

Pump manufacturers publish different values for minimum flows in technical publications or on performance curves, but what does it all mean, and what should pump operators do with this information? Is there a difference between minimum flow and minimum continuous stable flow (MCSF)? What happens if you pump below these stated values? And what are some ways to protect your pump against low-flow conditions?

Like many terms in the pump world, the meaning of “minimum flow” has shifted and changed throughout the years, as we as an industry have learned more about the effects of low-flow pumping on pump life.

The minimum flow used to be a point at which pump manufacturers drew a line in the sand. They thought operating below this low threshold would quickly result in complete failure of the pump.

As you may have guessed, the effects of low flow are not quite this black and white. If a pump manufacturer states minimum flow is 10 GPM, you won’t have an instant failure the minute you dip to 9 GPM, and likewise, you won’t have the best, longest pump life operating at 11 GPM.

Rather than black and white, think of a gradient scale from black to grey to white, moving from zero flow to the best efficiency point (BEP). The zero flow is black and very bad for the pump. The BEP is white and where you will get the longest, most trouble-free operation. Everywhere in between is a shade of grey. As we move left from the BEP, we run into things like suction or discharge recirculation, cavitation, vibration, and temperature rise.

Minimum Flow vs Minimum Continuous Stable Flow

Today it is common for pump manufacturers to publish more than one value in relation to minimum flows. For instance, the Carver Pump RS Multistage Ring Section pump has two values published for every size and rotational speed: minimum flow and minimum continuous stable flow (MCSF).

Our minimum flow value is the lower of the two values and is an intermittent minimum flow, meaning the pump can operate down to this point intermittently but should never operate below this point because it would lead to temperature rise, noisy operation, and excessive vibration.

Our MCSF value is greater than the minimum flow value, and the pump should operate at or above this point to achieve satisfactory bearing and seal life. Regular operation below the MCSF value will shorten the mean time between failure (MTBF) of the pump and can cost the operator both repairs and downtime.

Protection from Low Flow

So how can you protect your pump against the minimum flow? There are two main ways to prevent the issues associated with low-flow operation.

Continuous Recirculation

The first is continuous recirculation, which is exactly what it sounds like, a way of continuously recirculating the fluid from the discharge back to the suction side of the pump. This is typically done with an appropriately sized orifice, which ensures that even if the process flow rate drops to zero, sufficient flow passes through the opening, to keep the pump operating above MCSF.

The major benefit of continuous recirculation, aside from protecting your pump, is the simplicity of the setup. You simply add the MCSF to the process requirements. For example, if the process requires 100 GPM and the MCSF of the pump is 40 GPM, you would size the pump to operate at 140 GPM and continuously pass 40 GPM through the bypass. The disadvantages include higher energy costs associated with pumping at a higher flow rate and higher capital costs due to a larger pump and motor.

Active/Automatic Approach

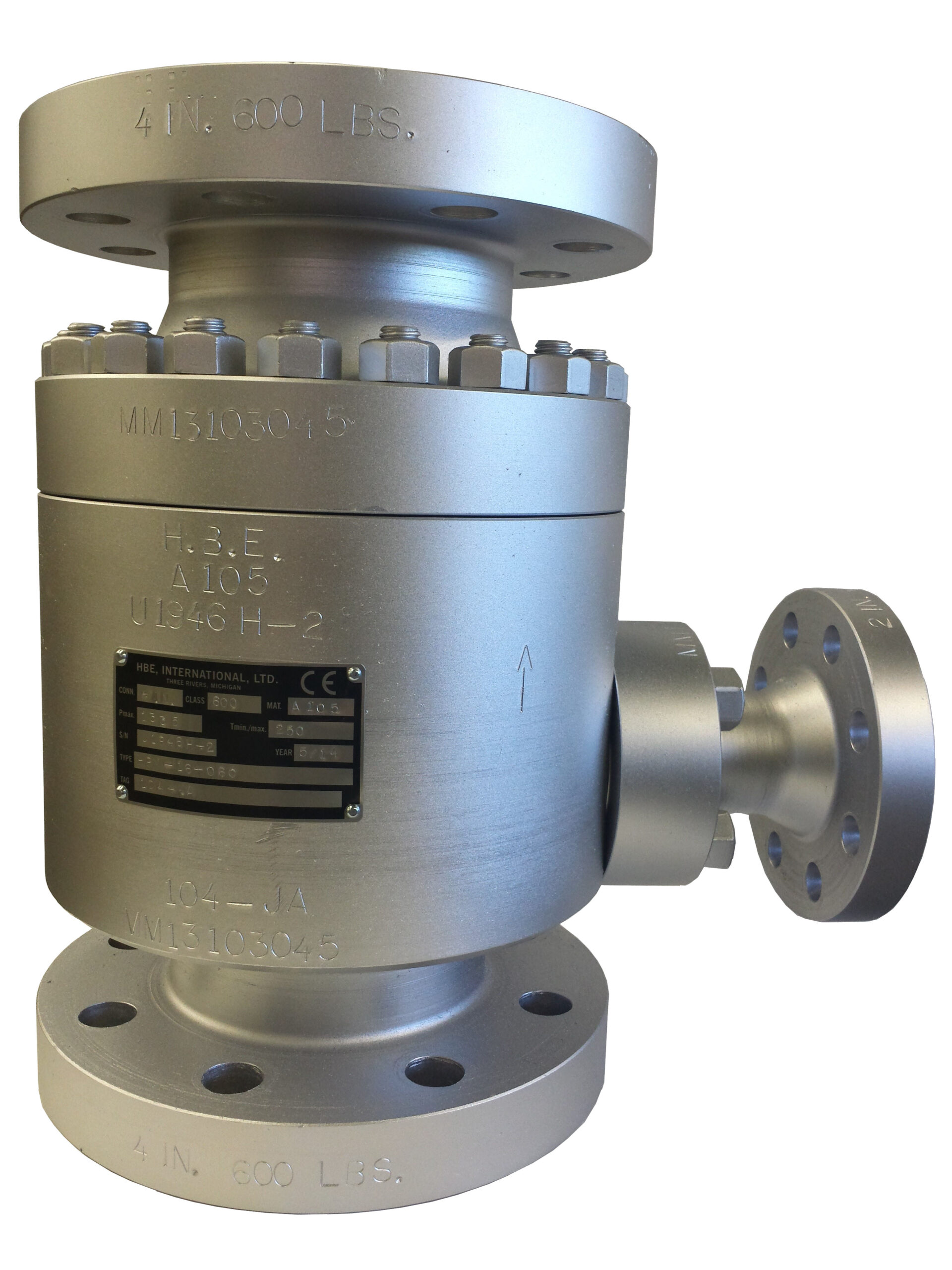

The other way to protect your pump against the minimum flow is to take an active or automatic approach. This can be done by monitoring the pressure or flow in a system and using a modulating valve to open up when a limit is reached.

Automatic recirculation valves (ARC valves) are one of our favorite ways to protect a pump against low-flow conditions. ARC valves are self-powered valves specifically sized for your application. As the pressure at the valve increases (and flow decreases), the valve slowly opens up to maintain MCSF for your pump. This is done without the use of a control system and is an easy way to protect the pump.

The main disadvantage of an automatic or active approach to protecting your pump against the minimum flow is the upfront expense, but compared to continuous recirculation, this protection usually pays for itself in reduced energy costs.