What’s the Difference Between a JM and JP Shaft Extension?

May 5th, 2020

Close coupled centrifugal pumps are attached directly to the face of a motor. They use the motor’s bearing and shaft, which makes these pumps more compact and economical. By contrast, frame-mounted pumps have their own bearing frame. For some applications, close coupled centrifugal pumps are the clear best choice due to the lower cost and a smaller footprint. In this article, we are focusing on two different varieties of the close-coupled centrifugal pump: those with a JP and those with a JM motor shaft extension.

To facilitate industry development of close coupled centrifugal pumps, the National Electrical Manufacturers Association (NEMA) developed a standard for close-coupled motors. This standard codifies the dimensions of the face where the pump frame attaches, as well as the length and diameter of the shaft where the impeller attaches.

For pump-specific motors, NEMA developed the standard around two different shaft lengths: JM (short) and JP (long). The shorter JM requires the use of a mechanical seal, while the longer JP shaft extension allows for the use of packing.

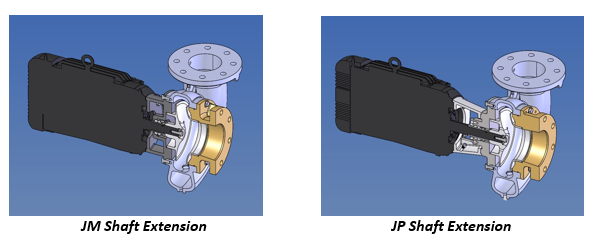

JM (Short) Shaft Extension

JM pumps are more compact, and at Carver Pump, our JM pump back cover also serves as the motor bracket, making for less costly construction. Although the shorter shaft extension allows for fewer seal options, it does have an important advantage: better seal life. This is because an important contributor to long seal life is limited vibration and radial movement at the seal face.

With a JM shaft extension, the distance from the inboard motor bearing to the seal face is shorter than with a JP shaft. Since the fluid forces acting on the impeller will always place some force or vibration on the impeller, the shorter shaft will not only place a lower torque on a JM shaft but also lead to lower deflection at the seal face, ultimately contributing to better seal life.

JP (Long) Shaft Extension

The JP shaft extension is the longer of the two pump-specific motor standards. The longer JP means a greater distance between the face of the motor and the hydraulic center of the impeller. At Carver Pump, this means we design the pumps with a full seal chamber/stuffing box that can accommodate a variety of seals or packing.

Also possible is the use of single or double cartridge seals and nearly any type of seal flush plan. A possible downside is that the pump is larger than an identical pump with a JM shaft extension. Another consideration is that when hot fluids (> 250°F) are pumped, the longer JP shaft extension provides greater thermal separation from the motor bearing, contributing to better bearing life.

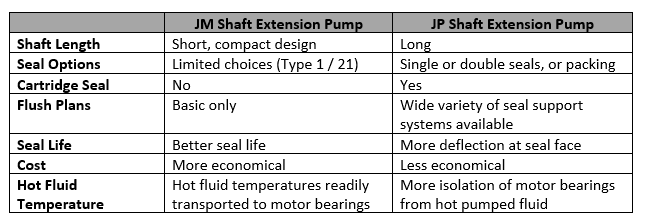

JM and JP Shaft Comparisons

Conclusion

Ultimately, the decision to go with a JM or JP shaft extension depends on the requirements of each process. The JP offers additional flexibility, but a JM can often get the job done at a lower cost. To serve a wide variety of industrial applications, we offer both JM and JP shaft extensions in our GH End-Suction Centrifugal Pump product line. GH Brochure